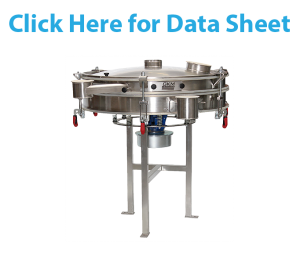

GKM Vibrating Screeners

For the control screening, fractionating and dedusting of dry, powdered and granular products. Particularly suitable for high feed rates and multi-deck separations of fine, lightweight products which are difficult to screen.

Features include:

- 1 to 3 decks per machine

- High screening efficiency

- Screen frames with twin-clamp rings for fast re-meshing on-site

- High acceleration; also suitable for solid-liquid separation and wet products

- Up to 100% availability in 24hr operation; maintenance-free motor

- Easy cleaning under the screener

- Optimum set-up of the vibrating springs, minimal transfer of vibrations

- Low noise levels of approx. 75 db(A)

- Screens down to 20 µm

- Size range 450 – 1500 mm diameter

GKM Vibrating Tumbler Screener Specifications

Vibrating Screeners

Vibrating Screeners

The solution at reasonable prices for the more simple dry and wet screening applications. For feed rates from 10 kg/h up to 10 t/hr.

| Areas of application: | For lower feed rates and simpler control screening operations; fractionating of dry, powdered and granular products, and liquid-solid separation; particularly well suited for heavy products and wet screening. | ||||||

| Particle feed size: | 1 micron up to 20 mm | ||||||

| Feed rates: | 1kg/h – 10 ton/h depending on machine size | ||||||

| Bulk densities: | 200 – 10000 grams/liter | ||||||

| Mesh openings: | 20 microns to 20 mm | ||||||

| Screens usable: | Stainless steel or plastic wire mesh fabric, perforated plates | ||||||

| No. of screen decks: | 1 – 3 per machine | ||||||

| Anti-blinding systems: |

– Rubber balls |

||||||

| Speed range: | 1500/3000 (1800/3600) min-1 at 50(60)Hz | ||||||

| Screen movement: | Three-dimensional, set to product | ||||||

| Amplitude: | 3 – 6 mm | ||||||

| Acceleration: | 3 – 6 g | ||||||

| Model sizes/ca. Ø: | KTS-V | 450 | 600 | 800 | 900 | 1200 | 1500 |

| Screening surface (m²): | 0.11 | 0.27 | 0.42 | 0.60 | 0.93 | 1.45 | |

| Motor power (kW): | 0.19 | 0.42 | 0.42 | 1.20 | 1.20 | 2.75 | |

| Materials: | Stainless steel | ||||||

| Surfaces: | Electro polished up to KTS-V 800, otherwise glazed inside and out with a high-grade surface finish. | ||||||

Advantages

Advantages:

- High screening efficiency, fast fine particle discharge, adjustable retention time.

- Delivered operationally ready and adjusted to each product.

- Up to 4 fractions simultaneously on each machine.

- High acceleration; also suitable for solid-liquid separation and wet products.

- Up to 100% availability in 24h operation; maintenance-free motor.

- Tough modular design with low part weights.

- Automatic centering of screening inserts and strong intermediate rings and covers for simple and fast assembly and screen changing.

- Low construction height by means of reduced intermediate ring heights.

- 100% dust and waterproof thanks to U-shaped EPDM or Silicone gaskets on the screen frames.

- Easy dismantling and cleaning of all body parts.

- Easy cleaning under the machine.

- Optimum set-up of the vibrating springs, minimal transfer of vibrations.

- Low noise level of approx. 75 db(A).

- Screen frames with twin-clamp rings for fast re-meshing on-site.

- Favorable prices and short delivery times.

Function

Function:

The machine is driven by a vibration motor attached directly to the center below the screen body. The screen body can vibrate freely and three-dimensionally by means of dislocation via precisely adjusted springs. The difference between this model and the KTS tumbler screening machines is the acceleration, which is 3-4 times higher at a comparatively low amplitude. Because the amplitude gets smaller towards the top with each additional screen deck, only 3 decks can be installed per machine.

The centrifugal force of the motor can be altered, as can the offset angle between the upper and lower flyweight in order to adjust the retention time of the product on the screens. The screen frames are equipped with 2 grooves and 2 fixation rings which enable easy and fast re-meshing on-site without much experience or any special tools, particularly where fine-mesh fabrics are involved. The KTS-V sizes 900-1500 can also be produced with the body parts of the KTS tumbler screening machines in order to satisfy the demands of certain food and pharmaceutical products, for example.