Kek Mills & Grinders

To meet the needs of the powder processing industry, Kemutec offers a wide range of milling technologies including standard particle size reduction machines and customized solutions to suit a wide range of applications.

Particle Size Range 150mm to 2-3mm (6” to 1/10”)

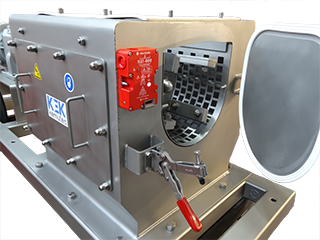

Designed to grind large lumps up to 150mm (6”), reducing them down to 2-3mm (1/10”), the heavy-duty and robust Kek Kibbler prepares the materials for further processing. Working in conjunction with other Kek mills, or as a stand-alone grinder, the Kek Kibblers are pre-breaker grinding mills also known as de-lumpers and product conditioners. The slow speed, high torque heavy-duty beater bars sweep materials against the contoured grinding screen, causing a combination of crushing impact, cutting, and abrasion, allowing size reduction to take place. The cantilevered shaft grinding beater bars make the Kibbler ideal for pharmaceuticals, food, and fine chemical applications.

- Cantilevered shaft

- High torque performance

- Low speed, dust, noise, and heat

- Rapid strip-down and reassembly

Particle Size Range D50 - 500μ to < 250μ

Recognized as an intermediate energy grinding mill, the Kek Cone Mill is one of the most versatile conical particle size reduction machines in the powder processing industry. The Kek Cone Mill is ideal for sizing in both wet and dry granulation processes because of its ability to take a wide range of feed material and produce an equally wide range of product. Traditional milling problems such as noise, dust, and heat generation, are eliminated due to the Kek Cone Mill’s gentle, low-energy size reduction technology.

- Highly efficiency, gentle grinding

- Low dust, noise, and heat

- Ideal for fatty, heat sensitive, moist products

Particle Size Range D50 - 100μ to < 20μ

The Kek Universal Mill provides safe, high-performance fine grinding and versatility. Various interchangeable grinding media support the Kek Universal Mill’s unsurpassed high energy, one-pass controlled size reduction. To fulfill the variety of processes and throughput requirements, a large range of grinding media and model sizes are available. Effective cleaning, trouble-free maintenance, integral design features, and easy access are inherent to Kek Universal Mill’s superior engineering.

- High-performance fine grinding

- Interchangeable grinding media

- Hygienic and easy to clean

Particle Size Range D50 - 20μ to < 5μ

Controlled, high energy grinding with integral particle size classification result into ultra-fine grinding capabilities and a greater control over particle size distribution with the PPS Air Classifier Mill. This tight control of the particle size is achieved by the fully adjustable rotor speed, airflow rate, feed rate, and classifier speed. The optional “clam shell” body design facilitates easy access for inspection, maintenance, and cleaning processes.

- Controlled particle size distribution

- Suitable for a wide range of applications

- Motor range from 5HP to 400HP