Kek Cone Mills

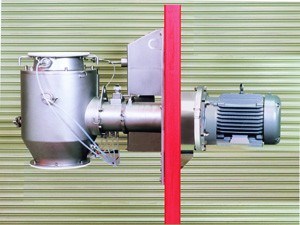

Kek Cone Mill for Gentle and Intermediate Grinding

“FULLY CUSTOM BUILT AND DESIGNED CONE MILLS”

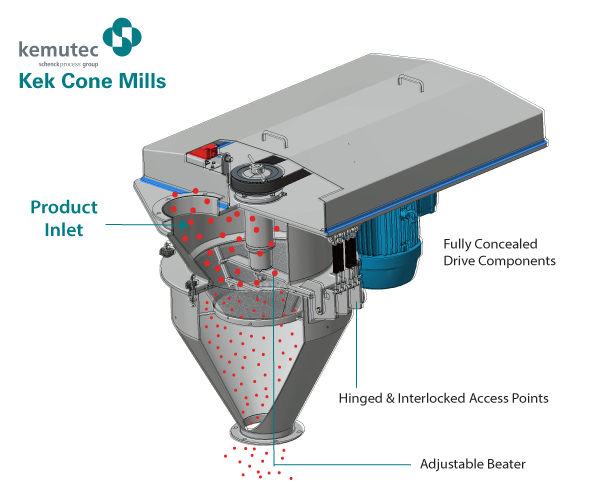

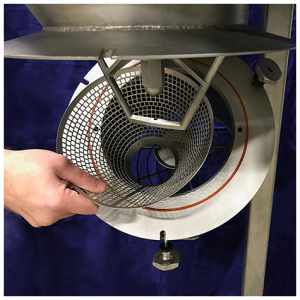

Kek Cone Mills are low energy and versatile mills for the gentle, intermediate grinding and deagglomeration of powders and granules.

Milled Particle Size Range – D50 500µ to < 250µ

Features Include:

- Versatile Intermediate Mill

- Variable Speed Drive

- Gentle Grinding Action to Minimize Fines

- Multiple Drive Configurations

- Low Heat Generation

- 7 Models in Range

How It Works

How It Works

Low Energy and high-speed mills with vertical inline product flow.

Benefits

- High Efficiency – Virtually all the energy input is utilized in the size reduction process.

- Gentle Grinding Action – Allows uniform size distribution, resulting in the minimum fines generation.

- Low Heat Generation – essential when milling fatty, sticky or heat sensitive products.

- Low Dust Levels – No need for air filtration. Keeps installation costs to a minimum.

- Low Noise – No costly acoustic protection. Mobile units can be used in any location.

- Flexibility – Freestanding mobile units, standard models as part of process systems and special custom units as an integral part of other capital equipment.

- Low Profile Design – Compact design results in low height and low profile installation.

Cone Mill Range

Product Range

Product Range

Kek Cone Mills are available in 7 sizes. From bench top 75 lab model through pilot plant sizes and on to full production models, which can process at many tons/hour.

The Kek Cone Mill Range

| Model | Cone Mill mm | Motor Size hp | Drive Type Options | Data Sheet Download |

| 75 | 75 | Fractional | Direct Drive | DS501 |

| 120 | 120 | 0.75 | Top Drive & Underdriven | DS349 |

| 170 | 170 | 3 | Top Drive & Underdriven | DS525 |

| 220 | 220 | 5 | Top Drive & Underdriven | DS476 DS497 |

| 340 | 340 | 10 | Top Drive & Underdriven | DS469 |

| 540 | 540 | 20 | Top Drive | DS520 |

| 680 | 680 | 25 | Top Drive | DS532 |

Design Options

Design Options

Design Options

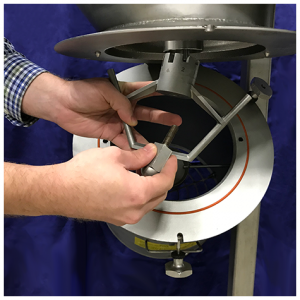

Customized Design

Kek Cone Mills are fully customized to suit the process, environment, cleaning and installation conditions for individual applications.

These include:

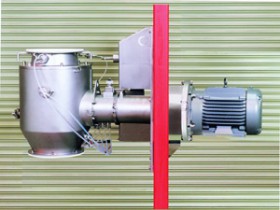

Drive Arrangements

- Top Belt Drive

- Top Direct Drive

- Under Belt Drive

- Under Gear Box Drive

- Remote or Thru-Wall Drives

Feed Arrangements

Mounting Arrangements

- On Mobile Support Frames

- On Masts and Pillars for Lift and Swivel Capabilities

Cleaning

- Fully Immersible Grinding Chambers & Shaft Seals

- Additional CIP / SIP Spray Nozzle

Applications

Applications

Applications

Kek Cone Mills are versatile mills for gentle grinding and deagglomeration with typical applications including:

Pharmaceutical Industry

- Dry Granulation

- Wet Granulation

- Tablet Rework and Regrind

Food Industry

- Coarse Sugar Grinding

- Cookie Rework

- Candy and Chocolate Bar Rework

- Dairy Powder Deagglomeration

- Bread Crumbing

- Rusk Grinding

Chemical Industry

- Detergent Tablet Rework

- Color extension of dye powder in blends

- General deagglomeration processing