Kek Mills & Grinders

Particle Size Range 150mm to 2-3mm (6” to 1/10”)

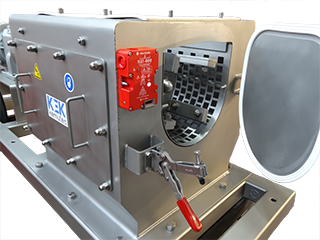

Designed to grind large lumps up to 150mm (6”), reducing them down to 2-3mm (1/10”), the heavy-duty and robust Kek Kibbler prepares the materials for further processing. Working in conjunction with other Kek mills, or as a stand-alone grinder, the Kek Kibblers are pre-breaker grinding mills also known as de-lumpers and product conditioners. The slow speed, high torque heavy-duty beater bars sweep materials against the contoured grinding screen, causing a combination of crushing impact, cutting, and abrasion, allowing size reduction to take place. The cantilevered shaft grinding beater bars make the Kibbler ideal for pharmaceuticals, food, and fine chemical applications.

- Cantilevered shaft

- High torque performance

- Low speed, dust, noise, and heat

- Rapid strip-down and reassembly

Particle Size Range D50 - 500μ to < 250μ

Recognized as an intermediate energy grinding mill, the Kek Cone Mill is one of the most versatile conical particle size reduction machines in the powder processing industry. The Kek Cone Mill is ideal for sizing in both wet and dry granulation processes because of its ability to take a wide range of feed material and produce an equally wide range of product. Traditional milling problems such as noise, dust, and heat generation, are eliminated due to the Kek Cone Mill’s gentle, low-energy size reduction technology.

- Highly efficiency, gentle grinding

- Low dust, noise, and heat

- Ideal for fatty, heat sensitive, moist products

Gardner Double Cone Blenders for powder processing provide superior blending of free-flowing powders and granules. They incorporate a gentle, low energy tumbling action, ideal for blending the most delicate and fragile products, through to the effective mix of very heavy and abrasive products.

The hygienic and easy to clean design Gardner Double Cone Blender for powder processing range is from 20 to 100,000 liters capacity and features unique multi-shear deflector mixing plates. Gardner Double Cone Blenders for powder processing can also be designed and built as processors for sterilizing and drying applications.

- Size range from 20 to 100,000 liters (1.5 to 3,500 cu. ft.)

- Hygienic design with no internal seals

- Minimal attrition when blending abrasive materials

Particle Size Range D50 - 100μ to < 20μ

The Kek Universal Mill provides safe, high-performance fine grinding and versatility. Various interchangeable grinding media support the Kek Universal Mill’s unsurpassed high energy, one-pass controlled size reduction. To fulfill the variety of processes and throughput requirements, a large range of grinding media and model sizes are available. Effective cleaning, trouble-free maintenance, integral design features, and easy access are inherent to Kek Universal Mill’s superior engineering.

- High-performance fine grinding

- Interchangeable grinding media

- Hygienic and easy to clean

Gardner Ribbon Mixers for powder processing are tried and tested horizontal mixers for the consistent batch and continuous blending of powder and granules.

Gardner Ribbon Mixers are tried and tested horizontal mixers for the consistent batch and continuous blending of powder and granules.

Designed with hygiene in mind the large, hinged lid and all-around access to the outlet allows for easy filling, emptying and cleaning. The Gardner Ribbon Mixers capacity ranges from 35 – 50,000 liters. Short mixing time combined with low energy, gentle action and high efficiency ensures that minor ingredients are dispersed homogeneously without the need for premixing.

- Size range from 35 – 50,000 liters (1.25 to 1760 cu. ft.)

- Batch or continuous mixing

- Available with Cantilever Shaft

- Liquid spray addition options

The high energy, high shear, high-speed Gardner Plow Mixer with cylindrical short aspect ratio mixing chambers, cuts mix times to a few seconds.

Available in a full range of sizes from 50 to 25,000 liters, models can be custom built to suit specific customer requirements, including alternative trough shapes, cantilever shaft design for easy access and the addition of side cutters or intensifiers for extra mixing shear.

- Size range from 50 – 25,000 liters (1.75 to 880 cu. ft.)

- High intensity mixing action

- Side cutters for extra shear energy

Particle Size Range D50 - 20μ to < 5μ

Controlled, high energy grinding with integral particle size classification result into ultra-fine grinding capabilities and a greater control over particle size distribution with the PPS Air Classifier Mill. This tight control of the particle size is achieved by the fully adjustable rotor speed, airflow rate, feed rate, and classifier speed. The optional “clam shell” body design facilitates easy access for inspection, maintenance, and cleaning processes.

- Controlled particle size distribution

- Suitable for a wide range of applications

- Motor range from 5HP to 400HP

The ultimate flow control valve for powders and granules. Designed with a concentrically closing fabric or elastomer diaphragm, the Mucon Iris Diaphragm Valve controls the flow of granular materials and powders accurately and efficiently. With 6 different models available and a range of sizes, Mucon for almost any powder flow applications.

- Available in sizes from 3” to 18” pending valve type

- Hygienic designs

- Manual, motorized, or pneumatic options

- No mechanical wear from abrasive products

- Ideal for “trickle-feed” and shutting off against material flow

A range of slide gate valves for powder flow isolation and slide gate applications, Mucon incorporates cutting edge technology and innovative design. Mucon’s long established reputation for high-quality powder valves continues with the addition of slide gate valves.

- Available from 4” to 12”

- Stainless Steel

- Manual, motorized, or pneumatic options

- Locking capabilities

- Durable for challenging materials

High-performance isolation valve capable of shutting off against flowing powders. This dependable and durable Mucon Disc Valve is designed to prevent jamming, withstand full vacuum above the disc, and up to 40psig below the disc.

- Available in sizes from 4” to 12”

- Manual and powered operation options

- Total shut off against material flow

- Aluminum, stainless steel, and cast-iron body options

Mucon’s VE range of stainless-steel butterfly valves for hygienic powder and flow control applications.

- Available from 4” to 12” diameter size range

- 316 stainless steel construction

- Pneumatic or manual operation

- Easy strip-down for maintenance and cleaning

Custom made mechanical bin activators and discharge aids for emptying powders from hoppers to silos. The Mucon Promoflow is one of the most effective silo and hopper discharge aids available, promoting the flow of any product.

- Low air consumption

- Whisper quiet operation

- Large size ranges from small hoppers to large silos

- Multiple screen shapes and designs