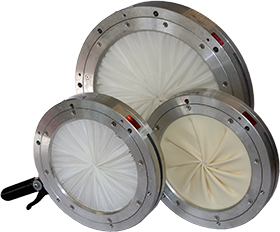

Mucon Iris Diaphragm Flow Control Valves

Mucon Iris Diaphragm Valve (IDV) utilizes a concentrically closing fabric or rubber diaphragm to accurately control the flow of powders and granular material.

Ideal for “trickle-feed” applications and shutting off against a flow of material.

Features include:

- No jamming (no mechanical components in contact with product)

- Full bore opening (no restriction to product flow).

- Trickle feed capability

- Hand, pneumatic or motorized options

- Slim design – low install height

- No mechanical wear by abrasive products

- Dust tight – no leakage to atmosphere

- Ability to seal around irregular objects

- Suitable for delicate products

- Hygienic designs available

- Easy to maintain and operate

Mucon has a range of 6 different models, each in a large range of sizes to meet the needs of virtually all powder flow applications.

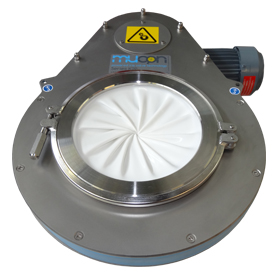

Mucon A2P Series Iris Diaphragm Valve

All purpose power operated IDV with electric or pneumatic operation

Mucon E Series Iris Diaphragm Valve

Heavy duty power operated IDV, with electric or pneumatic operation

Mucon JS Series Iris Diaphragm Valve

Large diameter manually operated valves specifically designed to control powder from Super Sack® Container discharge stations

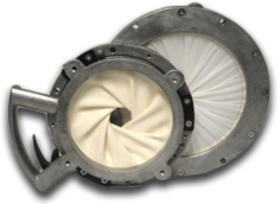

Mucon K Series Iris Diaphragm Valve

The stainless steel and easy strip down IDV for hygienic applications

Diaphragm Options

| DIAPHRAGM OPTIONS |

|---|

| DIAPHRAGM TYPE | FABRIC | COATED FABRIC | RUBBER |

| Powder | Yes | Yes | |

| Granules | Yes | Yes | Yes |

| Abrasive | + | Yes | |

| Hygienic | Yes | ||

| Pressure | Yes | ||

| Vacuum | Yes | ||

| Temperature | Yes | ++ |

+ Terylene is abrasion resistant

++ Viton Coated Terylene is ok for 200ºC.

Select most appropriate material using the diaphragm selection guide.

| DIAPHRAGM SELECTION GUIDE |

|---|

| APPLICATION | FOOD QUALITY WHITE RUBBER | RED RUBBER | ANTI-STATIC RUBBER | MOCK LENO | NYLON | ANTI-STATIC NYLON | HYPALON COATED NYLON | POLY-URETHANE COATED NYLON | TEFLON | TERYLENE | VITRON COATED TERYLENE |

| Powder below 150 mesh (104 microns) | •• | •• | •• | •• | •• | •• | •• | ||||

| Granules over 150 mesh | • | • | • | • | • | • | • | • | • | • | • |

| Lumps | •• | •• | •• | • | • | • | • | • | • | • | • |

| Slurry |

Under 1M header |

Under 1M header | Under 1M header | • | • | • | • | ||||

| Liquid | Under 1M header | Under 1M header | Under 1M header | • | • | • | • | ||||

| Air or gas | • | • | • | • | |||||||

| Abrasion resistance | • | •• | • | • | • | • | •• | •• | |||

| Acid | • | • | • | ||||||||

| Alkali | • | • | • | • | • | • | • | • | • | ||

| Max Temperature | 70ºC | 70ºC | 70ºC | 70ºC | 110ºC | 110ºC | 120ºC | 100ºC | 250ºC | 130ºC | 200ºC |

| Min Temperature | -40ºC | -40ºC | -40ºC | -40ºC | -75ºC | -75ºC | -35ºC | -40ºC | -75ºC | -75ºC | -40ºC |

| Pressure or vacuum | Below 0.14 bar | Up to 0.20 bar | |||||||||

| Food or pharm | •• | • | • | • | • | •• | • | ||||

| Infestation or mould growth | • | • | • | • | • | •• | •• | ||||

| Dangerous static | • | • | |||||||||

| Hygroscopic | •• | •• | • | • | |||||||

| Oil or fat content | • | • | •• | • | • | • | • | ||||

| Poor flow | •• | •• | •• | ||||||||

| Flammability | Inflammable | Inflammable | Infammable | Inflammable | Will not propagate a flame | Inflammable | |||||

| Weather resistance | Good | Excellent | Good | Very Good | Slow loss of strength | Excellent | Excellent | Excellent | Slow loss of strenght | Good | |

| Tensile strength kgs/cm² | 120 | 120 | 120 | 5.625 | 4.6 | 25% above base material | 25% above base material | 4.6 | 6.400 | 6.400 | |

| Elongation & break | 700% | 700% | 700% | 25% | 25% | 25% | 25% | 13% | 30% | 30% | |

| Cost factor 1-lowest 5-hightes | 2 | 2 | 5 | 1 | 1 | 1 | 1 | 1 | 5 | 1 | 5 |

| Availablity 1-best 5-worst | 1 | 1 | 5 | 3 | 1 | 4 | 3 | 1 | 4 | 2 | 4 |

Applications

| MUCON IDV APPLICATIONS |

|---|

| APPLICATION | AD | ADP | E | H | JS | K | DISC* |

| IBC’s – Discharge to atmosphere | Yes | Yes | |||||

| – Mating connection | Yes | Yes | Yes | Yes | Yes | ||

| FIBC’s – Throttle neck | Yes | Yes | Yes | Yes | |||

| OTHER APPLICATIONS | |||||||

| Isolation only | Yes | ||||||

| Flow control | Yes | Yes | Yes | Yes | Yes | Yes | |

| Open / close – frequent | Yes | Yes | Yes | Yes | |||

| – infrequent | Yes | Yes | |||||

| High BD (1600 kg/m³+) | Yes | Yes | Yes | Yes | |||

| Pressure / vacuum (up to 3 bar)* | Yes | ||||||

| High temperature (250ºC+) | Yes | ||||||

| Hygienic / easy to clean | Yes |

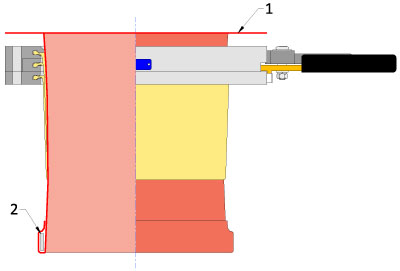

Installation

Installation of a Mucon Valve

The diagram shows the ideal way in which a Mucon Iris Diaphragm Valve should be installed. If the recommendations are followed, a prolonged diaphragm life will result. The AD, JS & K series of valves have lever slots, which allow the control levers to move through 180°. Accordingly, installation requires a combination of through bolts and set screws to be used. If there is any misalignment of the ductwork connected to the valve, this can cause the lever slot to open or close. With a serious misalignment, the valve body will be under stress, which could lead to rapid wear taking place and the failure of certain components. All valves are fitted with a label indicating the directions of material flow.

Flanges must be flat and free from distortion.

Flanges must be flat and free from distortion.- Fixing bolt over and under lever slot must not protrude into the slot.

- For diaphragm length see inside brochure.

- 12mm clearance from base of open diaphragm.

- Inlet diaphragm 5mm smaller than inlet size of valve.

- Discharge diameter 10mm larger than outlet size of valve.

Use of Liners

Use of Liners

The use of a liner with a Mucon Iris Diaphragm Valve installation may enhance the operation and capability of the valve typically by –

- Acting as a hygienic and protective liner.

- Assisting diaphragm opening.

- Combating diaphragm wear.

Liners can be used on their own or with an adaptor.

1) Use As A Hygienic or Protective Liner

By inserting a liner through the diaphragm of the Mucon Iris Valve, you can isolate the valve components such as the body, clamp ring and diaphragm from the flow of potentially harmful or dangerous powders.

Typical Applications include:

- Lining the iris valve with a liner produces smooth powder contact surfaces resulting in a more hygienic and easier to clean assembly. This arrangement is especially good in Food, Pharmaceutical and other applications where powder hold-up is not desired.

- Lining of the iris valve to protect the valve components from potentially harmful and corrosive powders.

2) Liners to Assist Diaphragm Opening

Where a fabric diaphragm is specified, it is always necessary to have a certain weight of material acting downwards to make it open fully. If the material has a tendency to bridge, often the diaphragm will only partially open.

If a flanged liner is hung through the valve (1) with weights of stainless steel sewn in the hem of the liner (2), this will assist in opening. (See Illustration)

If a flanged liner is hung through the valve (1) with weights of stainless steel sewn in the hem of the liner (2), this will assist in opening. (See Illustration)

Liners also reduce the effort required to operate valves

Various powdered materials exert differing pressures on a diaphragm. Normally a Mucon Iris Diaphragm Valve is easily operated, but on occasions some free flowing products exert a high static load on a valve and the control lever becomes difficult to operate. This is due largely to two things:

- The load exerted by the product forces the various layers of diaphragm material tightly together and when the control lever is operated, these try to rotate against each other.

- It has been observed that when a Mucon Iris Diaphragm Valve operates, the material in the column adjacent to the top face of the valve tries to turn as the valve is opened.

Both of these problems can be eliminated by the use of a liner.

3) Liners to Combat Diaphragm Wear

The length of life of a diaphragm is not easily quantified because of the many variables involved such as:

- Number of operations per day.

- Amount of material passed per day.

- The abrasiveness of the material.

In our experience the life of a diaphragm can vary between a few months and many years. Where the life can be measured in months it is often beneficial to consider the use of a liner.

The most frequently used liner material for combating abrasion is LINATEX rubber. This is a natural rubber with a better resistance to abrasion than steel. Where this is used it is important that a fabric diaphragm is used in the valve.

For in-line applications a double flange liner can be used.