Mucon Hygienic Oyster Butterfly Valves

Mucon offers a range of stainless steel hygienic Oyster™ Butterfly Valves for powder isolation and flow control applications.

Range Includes:

- Mucon Oyster™ Compact Butterfly Valve

- Mucon Oyster™ Flowmaster Multi-Blade Dosing Valves

- Mucon Oyster™ Tabmaster Soft-Edge Tablet Valves

- Mucon Oyster™ Composite Valve

Features Include:

- 316 Stainless Steel Construction

- 4″ to 12″ Diameter Size Range

- Manual or Pneumatic Operation

- Easy Strip-down for Cleaning and Maintenance

Oyster

Mucon Oyster™ Compact Butterfly Valve

Mucon Oyster™ Compact Butterfly Valve

The Oyster™ butterfly valve compact series features the patent Clamshell clamp system, widely acknowledged as the most compact, hygienic and user-friendly stainless-steel flow control valve on the market.

All Oyster™ branded sanitary butterfly valves are designed according to cGMP standards, for trouble free operation and easy maintenance. The stainless-steel flow control valve design ensures optimal hygienic and functional characteristics and eliminates recesses with hard-to-clean corners. Oyster™ branded valves are manufactured to exacting tolerances and finished to the highest pharmaceutical standards.

The Mucon Hygienic Oyster™ Compact Butterfly Valve is available in a vast range of models, which include:

- 4″ to 12″ diameter available

- Manual or Pneumatic Operation

- Flanged and Triclover connection options

- Bolted Body Design Available

Features

| Atex Certification |

II 2GD c IIB T4/T135°C – Ask for other zones |

| Diameter | DN 100* / 150 / 200 / 250 / 300 – (4”*-6”-8”-10”-12”) *under development |

| CIP/SIP | Suitable for CIP and SIP |

| Operation | Hand lever or Pneumatic Actuator |

Specifications

| M.O.C. Contact Parts |

AISI 316L, C22, (other alloys available upon request) |

| M.O.C. Other Parts | AISI 304 |

| M.O.C. Seals (all FDC 177.2600 compliant) | SILICONE, EPDM, PTFE, FFKM, MFKM |

| Available onnections | TC BS 4825-3, TC ASME BPE, TC DIN32676, TC ISO285, TC OSAME A, Weld End, Mounting Collar Compact Series |

Tabmaster

Mucon Oyster™ Tabmaster – Compact Butterfly Valve

Mucon Oyster™ Tabmaster – Compact Butterfly Valve

The flexible leaf is co-moulded in FDA compatible silicone and gives the flexibility necessary to ensure no damage to tablets or capsule being processed. The Oyster™ compact series features the patent Clamshell clamp system, widely acknowledged as the most compact, hygienic and user-friendly valve on the market.

All Oyster™ branded sanitary valves are designed according to cGMP standards, for trouble free operation and easy maintenance. The valve design ensures optimal hygienic and functional characteristics and eliminates recesses with hard-to-clean corners. Oyster™ branded valves are manufactured to exacting tolerances and finished to the highest pharmaceutical standards.

The Mucon Tabmaster Butterfly Valve is available in a vast range of models, which include:

- 4″ to 12″ diameter available

- Manual or Pneumatic Operation

- Bolted Body Design Available

Features

| Atex Certification |

N/A |

| Diameter | DN 100* / 150 / 200 / 250 / 300 – (4”*-6”-8”-10”-12”) *under development |

| CIP/SIP | Suitable for CIP and SIP |

| Operation | Hand lever or Pneumatic Actuator |

Specifications

| M.O.C. Contact Parts |

AISI 316L, C22, (other alloys available upon request) |

| M.O.C. Other Parts | AISI 304 |

| M.O.C. Leaf | Co-moulded Silicone (FDA 177.2600 compliant) |

| M.O.C. Seals (all FDC 177.2600 compliant) | SILICONE, EPDM |

| Available connections | TC BS 4825-3, TC ASME BPE, TC DIN32676, TC ISO285, TC OSAME A, Weld End, Mounting Collar Compact Series |

Flowmaster

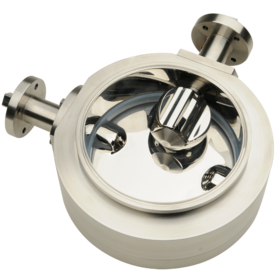

Mucon Oyster™ Flowmaster Compact Multi-Blade Dosing Valve

Mucon Oyster™ Flowmaster Compact Multi-Blade Dosing Valve

Multi-lobe valve designed to enable the controlled discharge of bulk powders, for example from a hopper into a machine. The Oyster™ compact series features the patent Clamshell clamp system, widely acknowledged as the most compact, hygienic and user-friendly valve on the market.

All Oyster™ branded sanitary valves are designed according to cGMP standards, for trouble free operation and easy maintenance. The valve design ensures optimal hygienic and functional characteristics and eliminates recesses with hard-to-clean corners. Oyster™ branded valves are manufactured to exacting tolerances and finished to the highest pharmaceutical standards.

The Mucon Oyster™ Flowmaster Compact Multi-Blade Dosing Valve is available in a vast range of models, which include:

- For Flow Control of Powders and Granules

- 4″ – to 12″ diameter available

- Spring Return or Pneumatic Operation

- Flanged and Triclover connection options

- Bolted Body Design Available

Features

| Atex Certification |

II 2GD c IIB T4/T135°C. Ask for other zones |

| Diameter | DN 100* / 150 / 200 / 250 / 300 – (4”*-6”-8”-10”-12”) *under development |

| CIP/SIP | Suitable for CIP and SIP |

| Operation | Spring Return or air/air Pneumatic Actuator |

Specifications

| Rotor |

6 lobes (for further tech. details, refer to the available datasheet) |

| M.O.C. Contact Parts |

AISI 316L, C22, (other alloys available upon request) |

| M.O.C. Other Parts | AISI 304 |

| M.O.C. Seals (all FDC 177.2600 compliant) | SILICONE, EPDM, PTFE, FFKM, MFKM |

| Available connections | TC BS 4825-3, TC ASME BPE, TC DIN32676, TC ISO285, TC OSAME A, Weld End, Mounting Collar Compact Series |

Composite

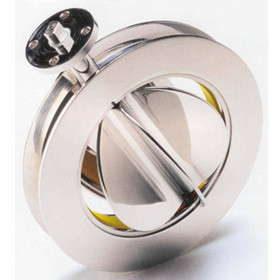

Mucon Oyster™ Composite Valve

Mucon Oyster™ Composite Valve

The ideal choice for the discharge and volumetric dosing of powders, particularly in a pack-off system. The ingenious design of the valve ensures optimal filling rates and dosing accuracy. It can be easily customized to suit individual customer requirements

All Oyster™ branded sanitary valves are designed according to cGMP standards, for trouble free operation and easy maintenance. The valve design ensures optimal hygienic and functional characteristics and eliminates recesses with hard-to-clean corners. Oyster™ branded valves are manufactured to exacting tolerances and finished to the highest pharmaceutical standards.

The Mucon Oyster™ Composite Butterfly Valve is available in a vast range of models, which include:

- For Flow Control of Powders and Granules

- 6″ – to 12″ diameter available

- Pneumatic Operation

Features

| Atex Certification |

II 2GD c IIB T4/T135°C. Ask for other zones |

| Diameter | DN 150 / 200 / 250 / 300 – (6”-8”-10”-12”) |

| CIP/SIP | Suitable for CIP and SIP |

| Operation |

MAIN LEAF: 0°-90° Spring Return or air/air Pneumatic Actuator. DOSING BALL: 0°-180° pn. Actuator and/or 360° gear motor |

Specifications

| Dosing Ball |

6 lobes (for further tech. details, refer to the available datasheet) |

| M.O.C. Contact Parts |

AISI 316L, C22, (other alloys available upon request) |

| M.O.C. Other Parts | AISI 304 |

| M.O.C. Seals (all FDC 177.2600 complient) | SILICONE, EPDM, PTFE, FFKM, MFKM |

| Available connections | TC BS 4825-3, TC ASME BPE, TC DIN32676, TC ISO285, TC OSAME A, Weld End, Mounting Collar Compact Series |

Feeder

Mucon Oyster™ Feeder Valve

Mucon Oyster™ Feeder Valve

Metal/Metal construction makes the valve suitable for continuous operation by motor for large discharge volumes. Shaped valve body ensures control of product flow.

All Oyster™ branded sanitary valves are designed according to cGMP standards, for trouble free operation and easy maintenance. The valve design ensures optimal hygienic and functional characteristics and eliminates recesses with hard-to-clean corners. Oyster™ branded valves are manufactured to exacting tolerances and finished to the highest pharmaceutical standards.

The Mucon Oyster™ Feeder Butterfly Valve is available in a vast range of models, which include:

- For Flow Control of Powders and Granules

- 4″ – to 12″ diameter available

- Electric or Pneumatic Operation

Features

| Atex Certification |

II 2GD c IIB T4/T135°C. Ask for other zones |

| Diameter | DN 100* / 150 / 200 / 250 / 300 – (6”-8”-10”-12”) |

| Operation |

Electric and/or pneumatic gear motor |

Specifications

| Dosing Ball |

6 lobes (for further tech. details, refer to the available datasheet) |

| M.O.C. Contact Parts |

AISI 316L, C22, (other alloys available upon request) |

| M.O.C. Other Parts | AISI 304 |

| M.O.C. Seals (all FDC 177.2600 complient) | SILICONE, PDM, PTFE, FFKM, MFKM |

| Option | Also available c/w ClamShell clamp (Compact System) |

| Available connections | TC BS 4825-3, TC ASME BPE, TC DIN32676, TC ISO2852, TC OSAME A, Weld End, Connecting Flanges |