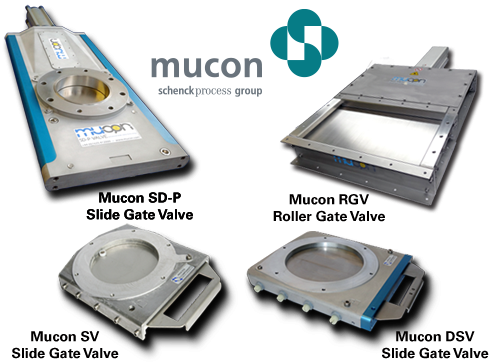

Mucon Slide Gate Valves

Mucon is proud to present a range of general industry Slide Gate Valves for dry particle processing. With the long established Mucon reputation as suppliers of quality powder valves, the Mucon Slide Gate Valve provides a great addition to the range.

Mucon Slide Valve Range:

- Moving Orifice Slide Gate Valve – SD-P Handwheel or Pneumatic Operation

- Single Flange Slide Gate Valve – SV Manual Operation

- Double Flange Slide Gate Valve – DSV Manual or Pneumatic Operation

- Roller Gate Slide Valve – RGV Handwheel or Pneumatic Operation

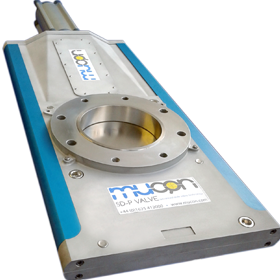

SD Pneumatic

The Mucon SD-P In-Line Pneumatic Actuated Slide Gate Valve

The Mucon SD-P In-Line Pneumatic Actuated Slide Gate Valve

Cutting edge technology for in-line shutoff applications, pneumatically actuated for remote operation.

The Mucon SD-P provides the latest in advanced Slide Gate Valve technology for the dry powder processing and bulk solids handling industries. Drawing on more than 60 years experience in the powder handling sector, Mucon has developed a range of valves to satisfy demanding customer requirements in product shut-off applications.

Its robust but simple design boasts a patent application with more than 53 innovative claims; making the Mucon Slide Gate Valve for dry particle processing, one of the most advanced valves of its type on the market today.

Construction

- Stainless steel slide gate blade

- Body in cast aluminum alloy with stainless steel bore liners

- Guards in aluminum alloy

- Blade gland packing from PTFE braid

- Slide sealing plates in Ertalyte® PET-P Plastic. A high-grade polymer with excellent temperature stability and wear resistance (FDA approved for food contact)

Applications

- Any bulk material handling application requiring the positive shut-off or full bore flow

- Mixer or blender fill or discharge chute

- Low pressure conveying lines

- Plastic pellet loading systems

Options

- Polished slide gate blade

- Other materials available for slide blade and bore liners

- Open and closed position indication switches

- Open and closed solenoid control bundle

Benefits

- Uninterrupted smooth bore when the valve is fully open

- Effective fully sealed closure

- Self-cleaning slide gate blade

- Dust-tight operation

- Extremely low maintenance

- Smooth, efficient operation

- Slim design

Features

- Powered by low friction, high-efficiency pneumatic cylinder

- Provision for ‘earth’ tags where there is potential for static electricity generation

- Lifting points provided at the valve center of gravity

- Flange dimensions to DIN or ANSI patterns

- Rated for up to +1barg conveying pressures

- ATEX certified to 1D/2D categories

- Size Range 150mm, 200mm & 250mm with other sizes available soon

SD Hand Wheel

The Mucon SD-H In-Line Hand Wheel Actuated Slide Gate Valve

All the technology of the SD range, but with a simple handwheel operation.

Construction

- Same as Mucon SD-P Slide Gate Valve (Above)

Applications

- Any bulk material handling application requiring the positive shut-off or full bore flow mixer or blender fill or discharge chute

- Low pressure conveying lines

- Plastic pellet loading systems

Options

- Polished slide gate blade

- Other materials available for slide blade and bore liners

Benefits

- Suitable for both gravity feed and low pressure conveying applications this latest innovation by the Mucon design team is feature rich at a surprisingly competitive price.

Features

- Operated by a multi-start drive screw via a large radius hand wheel

- Provision for ‘earth’ tags where there is potential for static electricity generation

- Lifting points provided at the valve center of gravity

- Flange dimensions to DIN or ANSI patterns

- Rated for up to +1barg conveying pressures

- ATEX certified to 1D/2D categories

- Size Range 150mm, 200mm & 250mm with other sizes available soon

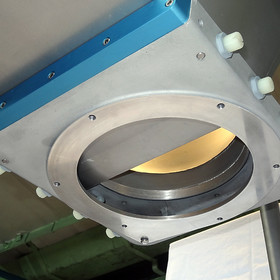

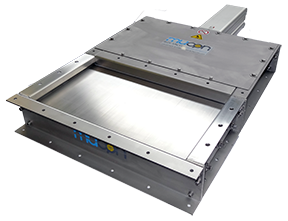

DSV Slide Gate Valve

The Mucon DSV Slide Gate Valve – Double Flange

The Mucon DSV Slide Gate Valve – Double Flange

Simple, cost-effective isolation solution for powders, granules, and pellets; for infrequent operation.

Overview

Ideal for in-line or open discharge applications, the Mucon DSV Slide Gate Valve provides a simple but extremely effective means of controlling and isolating the flow of powders, granules and pellets.

This simple but feature rich Mucon Slide Gate Valve is manufactured to our high standards and available from stock.

Construction

- All body parts are manufactured from cast aluminum alloy

- Stainless Steel AISI 304 slide plate

Application

- Manually operated for the control or isolation of powders, pellets, and granules

- In-line installation into pipes, ducts and hopper outlets

- Open discharge from rigid or semi-rigid intermediate bulk containers, bins, hoppers, and other storage vessels

Options

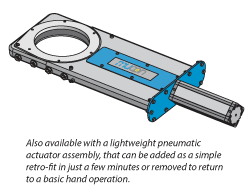

The DSV Slide valve will soon to be available with a lightweight pneumatic actuator assembly. This lightweight pneumatic actuator can also be added retrospectively in just a few minutes to an existing manual DSV Slide Valve

Benefits

The DSV Slide Gate valve has externally replaceable slide gate supports. Unlike other manual slide valves, the DSV doesn’t use an eccentric cam to support the slide gate. Our tapered supports, set on an angle, can be easily replaced while the slide gate remains in-situ and in the closed position.

Features

Features

- Top and Bottom connection flanges

- Robust construction, with integrated metal handle

- Anti-tamper locking facility – allowing the user to lock or tag the valve in the closed position

- Provision for ‘grounding’ tag where there is potential for static electricity generation

- Slim Design

- Cast aluminum body with machine flanged face

- Externally adjustable tapered and angled polymer slide supports allow the height of the slide gate to be finitely adjusted to compensate for wear

- Can be interchanged with the Series H Iris Valve as the flange dimensions are identical

- Size Range 150mm, 200mm & 250mm (300mm coming soon)

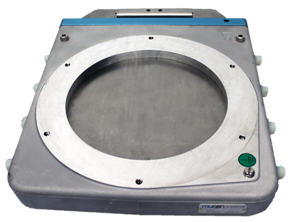

SV Slide Gate Valve

The Mucon SV Slide Gate Valve – Single Flange

The Mucon SV Slide Gate Valve – Single Flange

Simple, cost-effective solution for IBC closure; suitable for both rigid and semi-rigid Intermediate Bulk Containers

Overview

The Mucon Single Flanged Slide Gate Valve provides the ideal solution for isolating and discharging intermediate bulk containers or other storage units requiring no onward connection.

The simple but feature rich Mucon Slide Gate Valve is manufactured to our high standards and available from stock.

Construction

- All body parts are manufactured from cast aluminum

- Stainless Steel AISI 304 slide plate

Application

- IBC outlet closure and discharge

- Single, top flange mounting only

Options

- High temperature version available with metallic blade supports

Features

- Single top flange connection

- Hand operated – Simple but robust construction

- Facility to lock the valve in the closed position by a padlock or lockout tags

- Provision for ‘earth’ tag where there is potential for static electricity generation

- Slim Design

- Body in cast aluminum with machine flanged face

- Slide plate runners of Nylon 6 to withstand heavy loading

- Flange dimensions identical to the H Series Iris Valve for interchangeability

- Size Range 150mm, 200mm & 300mm

RGV Slide Gate Valve

The Mucon RGV Roller Gate Valve

The Mucon RGV Roller Gate Valve

Designed to be as modular and configurable as it is robust and reliable.

Ideal for heavy duty and large scale applications. Patented blade support ensures uninterrupted opening/flow control.

Features

- Uninterrupted opening due to our patented blade support system

- Heavy-duty construction for arduous applications

- Self-compensating blade scraper seal keeps the product contained and also cleans the blade during operation

- All valve seals and guides can be replaced in-situ

- Easily adapted for round outlets or ducts

- Steel rollers as standard

- Fast and smooth blade action

- Available in a variety of materials and finishes

- Able to support high product loads

- Inlet baffle is available for use with extremely arduous application

- Modular design allows configuration of custom opening dimensions, including rectangular