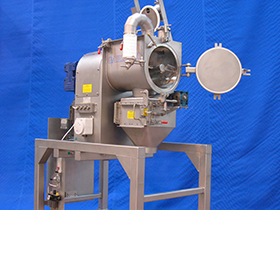

Gardner Ribbon Mixers

Gardner Ribbon Mixer for Rapid and High-Efficiency Powder Blending

Gardner Ribbon Mixers are tried and tested horizontal mixers for the consistent batch and continuous blending of pharmaceutical powders and granules.

Features Include:

- Batch or Continuous Mixing

- Range From 35L (1.25 cu. ft.) to 50,000L (1760 cu. ft.)

- High Efficiency Single Helix Ribbon Agitator

- Short-Aspect Ratio Mixing Troughs for Rapid Mixing

- Cantilevered Shaft Models Available

- Low Energy Mixing

Batch Mixers

Gardner Ribbon Mixer – Batch Mixers

Gardner Ribbon Mixer – Batch Mixers

Gardner Horizontal Ribbon Mixers are designed for the rapid and efficient blending of pharmaceutical powders and granular materials. Batch processing Ribbon Mixers are available in 2 product ranges:

L-Series Ribbon Mixers

- Small and compact batch Ribbon Mixers featuring:

- Model Range – 35L (1-1/4 cu. ft. ) to 400L (14 cu. ft.)

- Full-length opening top covers for maximum access

- Easily removable agitator

- Interrupted spiral agitator

- Large range of outlet valves available

Download Data Sheet

HE-Series Ribbon Mixers

Probably the most efficient batch Ribbon Mixer available, featuring:

Short-aspect ratio mixer trough

Short-aspect ratio mixer trough- High-efficiency “double helix” agitator with only 6 mixing blades

- Large top cover for ease of access

- Low-energy mixing

- Ideal for sticky powders

Download Data Sheet

Continuous Mixers

Gardner Ribbon Mixer – Continuous Operation

Gardner Ribbon Mixer – Continuous Operation

Gardner Continuous Ribbon Mixers are custom designed and built to meet the demands of individual process needs.

Based on the tried and tested Gardner Batch Ribbon Mixer technology, the continuous process mixers are adapted to receive, mix and discharge powdered and granular materials.

Typical features include:

- Interrupted Spiral Ribbon Agitator

- Long-aspect ratio mixing trough

- Adjustable ‘weir-type’ overflow outlet

- Total discharge valve fitted to trough

- Large access doors

- Rates from 250 lb/hr to over 100,000 lb/hr

Design Options

Custom Design

Custom Design

Gardner Ribbon Mixers can be customized and adapted to suit the varying demands of individual applications.

These typically include:

- Choice of mixing trough shapes – U-shaped or circular

- External jackets on the mixer trough for heating or cooling the mixer contents

- Pressure and vacuum capable vessels for drying, heating, cooling and sterilizing applications

- Liquid addition facilities including pressure spraying, atomizing and gravity sparge pipe.

- Cantilever shaft, with no non-drive end bearing or seal

- Range of various materials of construction

Applications

Applications

Applications

Gardner Ribbon Mixers are the workhorse of the powder mixing and blending industries.

Typical applications include:

- General Dry Powder Mixing

- Liquid Addition with Powders

- Drying of moist or damp powders

- Live storage of sticky powders

- Granulation of Powders

Gardner Ribbon Mixers can be used in the Food, Chemical, and Pharmaceutical Industries.