Kek Universal Mills

Kek Universal Mill for High Energy, One-Pass Grinding of Powders and Granules

Kek Universal Mills are high energy mills, with interchangeable grinding media to maximize processing versatility and capability.

Milled Particle Size Range – D50 – 100µ to < 20µ

Features Include:

- High Speed, High Energy, One-Pass Mill

- High Capacity Fine Grinding

- Interchangeable Grinding Media

- Temperature Controlled and Cryogenic Grinding Available

- Large Range From 5hp to 200hp drives

Universal Mill Range

Product Range

Kek Universal Mills are available in a large range of sizes, from small lab pilot units through to 200 hp production units.

Kek Universal Mill Range

Kek Universal Mill Range

Grinding Media Options

Grinding Media Options

As a Universal Mill, this grinder is capable of utilizing a number of different types of grinding media.

Selection of the optimum grinding media is usually dependent upon the individual application, with such factors as the material type, physical properties, infeed product size and milled product size being taken into consideration.

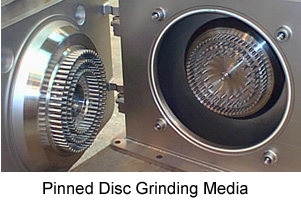

Pinned Disc

A pair of pinned discs with intermeshing pins. A rotating disc (rotor) is fitted to the mill drive shaft, with a fixed disc (stator) mounted on the inside face of the door.

Close tolerance gaps between the pins and rows of pins provide high levels of both impact and shear energy.

Grind Energy can be adjusted by varying pin numbers, pin shapes and rotational speed.

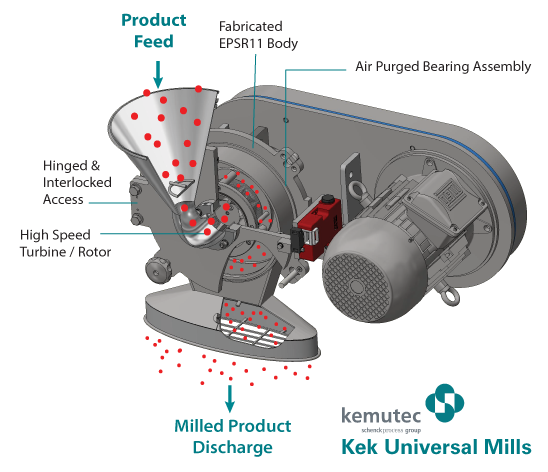

Turbine and Screen

A multi-bladed turbine rotates at high speed within a fixed outer screen assembly.

The speed of the turbine offers variability in the amount of impact energy impaired into grinding the material.

The outer screen assembly provides a degree of particle size classification by holding the material in the grinding zone. Varying the hole size in the screens will adjust the milled particle size distribution.

The outer screen assembly provides a degree of particle size classification by holding the material in the grinding zone. Varying the hole size in the screens will adjust the milled particle size distribution.

Shear energy can be added to the grinding process by the addition of cutter blocks, which are set into the cutter screen assembly.

Rib Track

Similar to the Turbine and Screen grinding media (above), Rib Track utilizes the same high-speed turbine. However, it benefits from the availability of more shear energy through the fitting of a full circumference rib track cutter block on the front edge of the outer stationary screen assembly. A full circumference screen is positioned behind the rib track to provide classification.

Custom Design

Custom Design

Kek Universal Mills benefit from varied and versatile system design capabilities, which can be customized to suit the demands of the individual applications.

The mill can be sited at elevated levels or at ground level and linked to the milled powder collection by either an integral hopper or by a remote filler – receiver (see below).

In addition, Kek Universal Mills benefit from customized process design options, typically including:

- Temperature Controlled Grinding – see applications

- Cryogenic Milling – see applications

- Inert Milling – see applications

- Explosion ProtectionExplosion relief through Bursting Panels

- Explosion suppression with a Quench or Suppression System

- Explosion containment with 10 bar PSR design

- System inerting by replacing combustible gases and air with inert gas such as nitrogen.

- Closed Loop Milling, fine grinding without the need for filtration.

- Compact design

- Minimal moisture uptake in milled powder

- 10 bar PSR capable

Applications

Applications

Kek Universal Mills are high capacity fine grinders for the size reduction of soft to medium hard and non-abrasive powders and granules.

Kek Universal Mills are high capacity fine grinders for the size reduction of soft to medium hard and non-abrasive powders and granules.

Typical Applications include:

Pharmaceutical Industry

- Fine Powder Grinding

- Fine Powder De-agglomeration

- Dry Granulation

Food Industry

Chemical Industry

- Sodium Bicarbonate

- Trona

- Sulfur

- Nitrates

- General Fine Powder Grinding

Special Applications

Temperature Controlled Grinding

Temperature controlled milling involves the use of liquid nitrogen as a cooling agent which is applied to the mill and collection system. This system is often employed to either improve processing properties of heat sensitive materials or give a specified milled product output from the mill where it is essential to eliminate temperature pick up during normal milling i.e. control of mill temperature from ambient mill temperature to -5°C.

Cryogenic Grinding

Cryogenic grinding systems also involve the addition of nitrogen but the temperatures are much lower and cooling is applied to the mill system and the feed product. The object is to embrittle products that are impossible to impact mill at ambient temperatures. By cooling them to temperatures of -150° C, it is possible to grind problem materials finely.

Cool and Cryogenic grinding will also provide the added benefit of inert explosion protection.