The Mucon Disc Valve – A Dry Powder Valve

The Mucon Disc Valve (Swing Gate Valve) was the result of a development exercise, where Mucon was challenged to produce a dry materials valve encompassing some of the advantages of Slide and Butterfly valves, but with none of their inherent disadvantages. The resultant design concept is simplicity itself; a factor which has been a major contribution to the Disc Valve’s reputation for reliability and longevity.

The Mucon Disc Valve (Swing Gate Valve) was the result of a development exercise, where Mucon was challenged to produce a dry materials valve encompassing some of the advantages of Slide and Butterfly valves, but with none of their inherent disadvantages. The resultant design concept is simplicity itself; a factor which has been a major contribution to the Disc Valve’s reputation for reliability and longevity.

How It Works

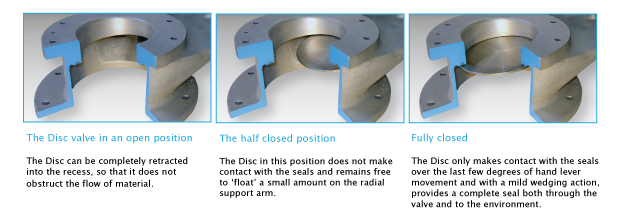

A free-floating stainless steel disc, supported on a radially acting arm swings across the underside of the orifice through which product flows. Around the orifice is an angled seat face, therefore, as the disc closes onto the seal, it adopts the same angle, resulting in a mild wedging action; providing an excellent seal even to the finest powders. The Mucon Disc Valve is available in manually or pneumatically actuation.

The disc slides over the angled seat by the minimum amount required to achieve a seal, reducing substantially any potential for mechanical wear. The absence of any guide-ways and the use of a radial disc action ensures that material cannot jam the valve during operation.

The only component not part of the valve body casting is the shaft, which rotates the operating arm. This is easily sealed by ‘O’ rings or, for high-temperature applications, by a stuffing box arrangement ensuring that no product can escape to the atmosphere.

A dovetail groove is machined into the seating face of the Disc Valve (Swing Gate Valve) to accept a specific ‘O’ ring best suited to the specific application. O-rings are required when there is a differential pressure across the valve. Their use is not essential for every application. For example, metal to metal sealing is used for those applications involving high temperatures.

The seat face is positioned out of the product flow and the outlet is at least 50mm larger than the inlet diameter. Both of these features ensure minimum wear to the valve, even when used with the most abrasive products.

Our standard Disc Valves are produced from a single body casting, to meet the needs of customers wishing to use Disc Valves for applications requiring frequent thorough cleaning.

100mm and 200mm Mucon Disc Valves also come in an ‘Easy Maintenance’ configuration that have operating internal parts, which can be removed and maintained in situ. In addition, the seat is renewable and does not necessarily have to be of the same material as the valve body.

All valves are furnished with blanked-off tappings to the Disc cavity. These have been introduced to accept air purging or to accommodate clean-in-place connections. This facility is especially useful when handling Hygroscopic materials or where frequent cleaning of the valve is required.

Features

- Valve outlet is larger than the inlet ensuring full bore, uninterrupted flow of product, without transitional hang-up

- Seating face is protected from direct abrasion

- Angled seating face ensures no jamming, as guide-ways are not used for the slide plate to run on

- The disc is free floating on a radially moving arm. The disc, as a result, takes up the same angle as the seating face, thus creating a slight wedging action and dust tight seal, as well as compensating wear on the disc

- Disc is totally retracted from the area of product flow

- Standard Disc Valves are made from one-piece body casting

- Easy Maintenance 200mm and 100mm valves are made in two sections, allowing the valve internals to be removed while the valve is in-situ

- Easy Maintenance valves also have a replaceable seating face

- Three purge points are included as standard for easy cleaning

Benefits

- Non-jamming action

- 100% product shut-off

- Full bore opening

- Dust tight to atmosphere

- Low maintenance

- High temperature applications

- Up to 2.7 Bar pressure BELOW disc

- Full vacuum ABOVE disc

- Able to close through a static column

- Able to seal against vapors, escaping to atmosphere

- Offers many years of reliable service

- Increased productivity

- Offers customers lower Total Cost of Ownership