Traditional solutions to this problem are highly manual and frequently involve operators standing by to take the product back out of the receptacle to get back to target weight. It is frequently a weak spot in otherwise tightly controlled processes.

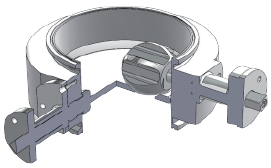

A far more sophisticated solution to this problem is the Mucon Oyster™ Composite Valve, so-called because it is composed of two separately controlled closing elements.

· The Main Leaf looks and operates like a butterfly valve and can be opened and gradually closed to enable the discharge of the bulk of the quantity required. It is different from a standard butterfly valve in that the leaf has a hole in it to one side, in which is located the second closing element.

· The Dosing Ball. Once the greater part of the target quantity has been discharged through the main leaf and the main leaf is closed, the dosing ball comes into operation. It is designed to rotate backward and forward through 180° and as it does so discharge “teaspoon-full” quantities of the product until the target weight is reached.

The valve lends itself extremely well to automation and with a carefully calibrated control system, it can deliver perfect fine dosing time after time, with no manual intervention.

It is particularly suited to free-flowing powders. However, where the product being handled tends to bridge, the Oyster™ Composite Valve (unlike any other valve of its type) can be supplied with a bridge-breaker which operates contin uously while the dosing ball is in operation to break down any bridge which might form and ensure reliable product dosing.

uously while the dosing ball is in operation to break down any bridge which might form and ensure reliable product dosing.

For applications with WIP systems, a version of the Oyster™ Composite Valve is under development that will be water tight in the closed position. This further distinguishes this exceptional valve from its competition.