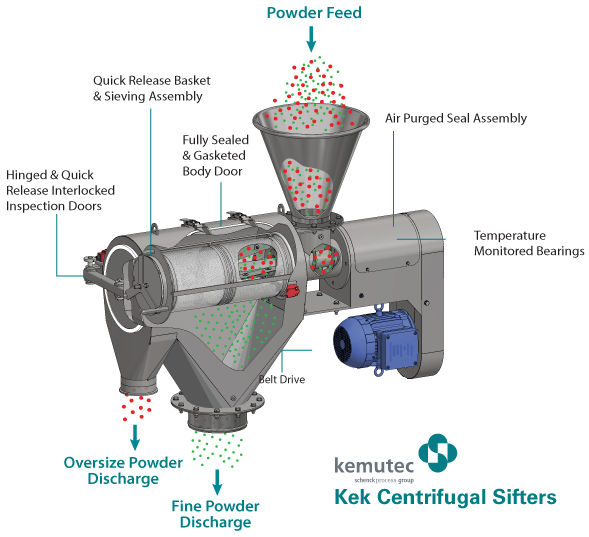

Kek Centrifugal Sifters

Class Leading and Industrial Kek Centrifugal (Rotary) Sifter for Powder and Granule Processing

‘EASY CLEAN’ CANTILEVER DESIGN SIFTERS

The Cantilever design Kek Centrifugal (Rotary) Sifter is based on the tried and tested Kek Centrifugal Sifter range. The ‘Cantilever’ design offers users high standards in hygiene and ease of powder processing operation that are unprecedented.

Features include:

- High Capacity & High-Efficiency Sifting

- Gravity and Inline Pneumatic Conveying Designs

- Cantilever Shaft – No Oversize Bearing or Seal

- 30 Second Screen Changes

- 7 Model Sizes in Range

- Rates – From a Few Pounds to Over 200,000 lb/hr

- Easy Disassembly for Cleaning and Maintenance

Inline Sifter

In-line Pneumatic Conveying Applications

In-line Pneumatic Conveying Applications

Industrial Kek Centrifugal (Rotary) Sifters for powder processing, can be used for direct in-line installation into pneumatic conveying lines.

Models available for both:

Typical Design Features Include:

- Heavy duty construction

- Up to 12 psi operating pressure

- Standard pipe stub connections

- Various screen media options

- Available in 3 standard sizes

• K650CP • K800CP • K1100CP - Many oversize collection options available

Typical operational benefits:

- Direct connection into conveying pipeline

- Compact design

- Can be mounted at floor level

- Easy access for cleaning and maintenance

- No need to disentrain conveying air before sifting takes place

Sifter Range

Design Options

Design Options

Design Options

Industrial Kek Centrifugal (Rotary) Sifters can be customized to suit the demands of process, environment and installation requirements.

Typical optional design features include:

- Drive arrangement

- Hazardous area electrics

- Pressure rated design

- Gas inerting

- CIP capability

- Special metals and alloys for construction

- High containment machines

- Screen protection or trash traps

- High containment and dust-tight connections

Special Applications and Designs

Special Applications and Designs

Kek Centrifugal (Rotary) Sifters are ideal for the sifting and processing of Powders and Granules in gravity and inline installations with typical applications including:

Kek Centrifugal (Rotary) Sifters are ideal for the sifting and processing of Powders and Granules in gravity and inline installations with typical applications including:

Policing – Check sieving and removal of foreign contaminants

Scalping – Check sieving and removal of oversize products

Classification – Separating of two fractions at a specific screen size

Deagglomeration – Breaking of soft lumps into powders

Dedusting – Removal of ‘fines’ from feed products

Liquid Straining – Removal of excess liquid from solid product by straining through the sifter screen

Product Dressing & Conditioning – Final dressing and conditioning of powder mixes to ensure optimum end product quality.

Special Applications and Designs

In addition, Kek Centrifugal Sifters are used for these special applications.

- Recovery of Products from Packaging

- De-Agglomeration of Raisins and Other Dried Fruits

- In-Line Vacuum Conveying Centrifugal Sifters

- In-Line Positive Pressure Pneumatic Conveying Centrifugal Sifters

- Powder Paint Spray Booth Recovery

- Flour Sieving Using Kek Centrifugal Sifters

- Kek ‘Insertable’ Mini Sifter

- Extruder Protection

Typical Industry Applications include:

Typical Industry Applications include:

Food Industry

- Flour sifting

- Ingredient check sifting

- Dairy powder sifting

- Bakery mix de-lumping and final dressing

Chemical Industry

- General fine powder classification

- Nylon flock deagglomeration

- Powder deagglomeration

- Powder Paint Check Sieving

Pharmaceutical Industry

- Check sieving of bulk pharmaceuticals

- Classification of active pharmaceutical ingredients

Screen Options

Screen Options

Kek Centrifugal Sifters are available with a number of various screening media options to suit the specific application needs

Kek Centrifugal Sifters are available with a number of various screening media options to suit the specific application needs

- Nylon Mesh – Most popular and versatile, benefiting from high throughput rates and a wide range of mesh sizes down to 30µ

- Steel Mesh – Wide size range and beneficial where applications require metal-detectable screen media

- Wedge Wire – Heavy-duty “slotted” type metal screen for abrasive check-sieving applications

- Perforated Plate – Heavy duty metal screen for high capacity check-sieving and abrasive applications

- Special Polymers – Similar to Nylon Screens but using special polymers that can be resistant to high temperatures, corrosive products and static electricity