Valentine’s Day Sweets with Kek Powder Processing Equipment

Valentine’s Day is here and 53.2 percent of Cupid’s followers will spend their hard earned Valentines Day cash on something sweet. Total candy spending is expected to top out at $1.7 billion; over 21% of these sales will be on holiday goodies.1 Another interesting note, men will spend on the average $190.53 on their significant other, while women will spend a mere $96.58 on their partner.2

So how does Kemutec’s Kek equipment factor into these stats? 170.9 tons of sugar per year3 is produced worldwide, to help in producing these goodies Kemutec Powder Processing Equipment is a major component in getting the sugar ready for production.

Kemutec offers a range of mills for sugar grinding, including:

Kemutec offers a range of mills for sugar grinding, including:

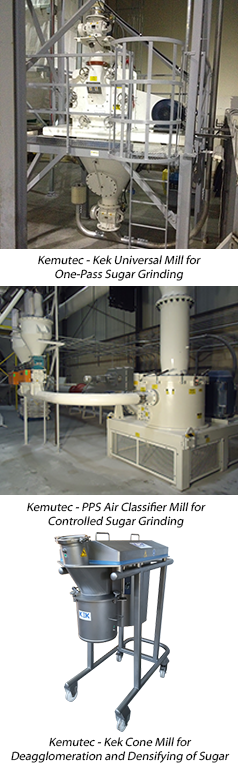

Kek Universal Mills for 6X, 10X Grades of Powdered Sugar

- One-pass sugar grinding

- Up to 15,000 lb/hr

- Large range – from 5 hp to 100 hp

The Kek Universal Mill provides high-energy one-pass fine grinding. Available with a variety of interchangeable grinding media, the Kek Universal Mill is capable of unsurpassed, versatile milling performance with a milled particle size range – D50 of 20µ to 100µ for most products. Process customization includes closed-loop mill design, 10 bar containment systems, temperature controlled grinding and full cryogenic grinding.

PPS Air Classifier Mills for 6X, 10X, 12X, 14X Grades of Powdered Sugar

- Controlled sugar grinding

- Up to 30,000 lb/hr

- Large Range – from 5 hp to 300 hp

The PPS Air Classifier Mill incorporates an internal air-classifying wheel with an independent drive giving precise control over “particle cut point” selection. Suitable for batch processing or continuous operation this range of mills serves all industries producing fine powders where control of grinding temperature and particle size distribution are of prime importance. PPS Mills have a controlled particle size range of D50 from 10µ to 30µ. They are available with fully opening “clamshell” body designs enabling easy access for rapid product changeover, inspection, cleaning, and maintenance.

Kek Cone mills for Deagglomeration and Densifying of White and Brown Sugar

- Gentle, low heat grinding action

- Low dust levels

- Particle size range: D50 from 500µ to <250µ

The Kek Cone Mill is recognized as one of the most versatile size reduction machines in the powder processing industry. Its ability to take a wide range of feed material and produce an equally wide range of product makes it ideal for intermediate sizing in both wet and dry granulation processes. The Kek Cone Mill provides a gentle low-energy form of size reduction and eliminates traditional milling problems including noise, dust, and heat. The gentle grinding action is capable of control within fine limits while maintaining a close particle size distribution with minimal fines generation, typically grinding from 25 mm to 250µ.

Read more about Kemutec’s range of Sugar Grinding Mills including explosion precautions.

1 https://www.franchisehelp.com/industry-reports/chocolate-industry-report/

2 https://www.linkdex.com/en-us/inked/valentines-day-statistics-for-marketers/