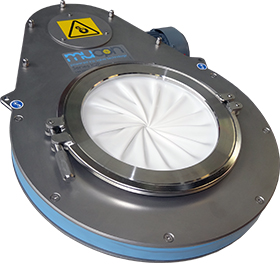

Mucon K Series Iris Diaphragm Valve

The Mucon K Series Iris Diaphragm Valve is a high-quality stainless steel valve, specifically designed for hygienic applications.

Features Include:

- Hand Lever and Powered Operation

- Electric Motor – Air Operation

- Size Range – 6” to 10” Diameter

- Double Diaphragm for Improved Performance

- Easy Strip-down Option

- Tool Free Strip Down Option Available

- All Stainless Steel Construction

- Multiple Diaphragm Materials Available

Applications

Clean Room Pass-Thru

Clean Room Pass-Thru

The sealing of removable, temporary cables, pipes and other service or process supply lines has long been a challenge facing clean room, isolation and glove box operators. Providing a gas or dust tight seal around the service lines while enabling the same lines to be easily removed when not in service or when cleaning is required has always been the major requirement.

The solution is a Mucon Iris Diaphragm Valve used to seal around both ends of the service lines as they pass through a wall or partition.

Traditionally used for the flow control of powders from hoppers and silos, the infinite variable open/close action of the diaphragm in the Iris Valve allows it to seal tight around service lines. The flexibility of the rubber or silicone diaphragm even allows a seal around multiple lines, pipes, and cables, regardless of shape, size or material of construction. (See Figure 1) Additional sealing is provided by the use of 2 diaphragms in each valve, totaling 4 diaphragms that provide a seal around the service pipes – 2 seals on each side of the wall. (See Figure 2)

When it is time to remove the service lines, the 2 valves are opened and the temporary supply lines are removed. With the use of a quick release clamp connection, the valves can be easily removed, leaving a simple plain outer pass-thru pipe in place in the wall. When not in use, the outer pass-thru pipe can be capped-off, allowing the clean room or isolator to be used without the temporary services.

Any necessary cleaning of the Iris Valve is achieved remotely and enhanced by its easy disassembly, all achieved without the need for tools. In addition, the Iris Valve components are suitable for autoclaving.

Any necessary cleaning of the Iris Valve is achieved remotely and enhanced by its easy disassembly, all achieved without the need for tools. In addition, the Iris Valve components are suitable for autoclaving.

The Mucon K Iris Diaphragm Valve provides the perfect solution for a temporary process supply line seal for clean rooms, isolators, and glove boxes.

Read more about the Mucon Series K Iris Diaphragm Valve for Clean Room Pass-Thru

Options

- Bolt mounted and Quick Release versions

- Mounting flanges with quick release clamps allow the Series K to be welded to the client’s equipment

- Available with Tri-Clover compatible connection flanges, ideal for cleanroom wall mounting (KD08 and KD10 only)

- Electro-polished Vee clamps allow the valve to be held to the mating flange

- Blanking plate is available so that the valve can be fitted to the outlet of double cone blenders or similar

- Multi-notching of hand operated valves is available for flow control

- Manual, pneumatic or electrical actuation

Clean Room Pass-Thru

Clean Room Pass-Thru